Contact: Dave Yeagly 510 486-7611

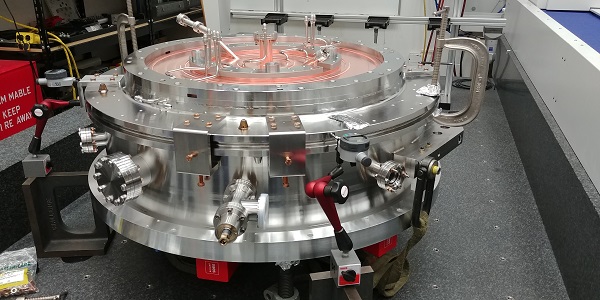

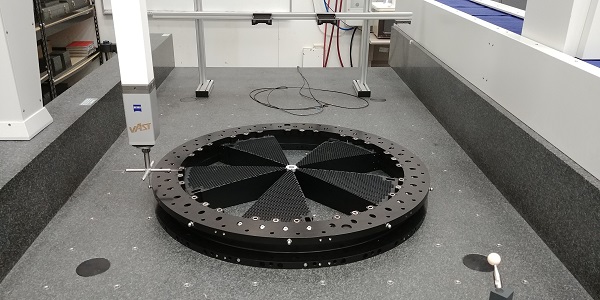

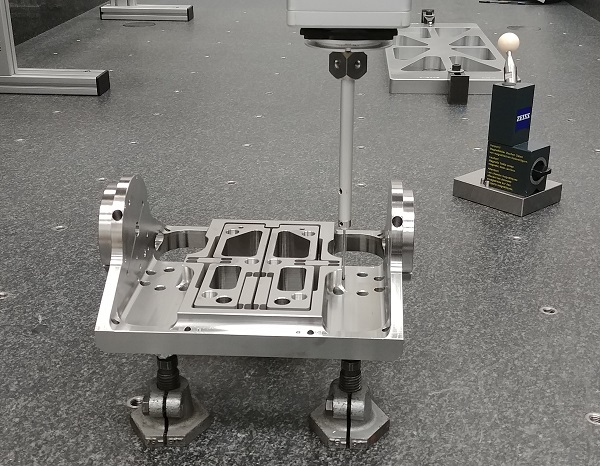

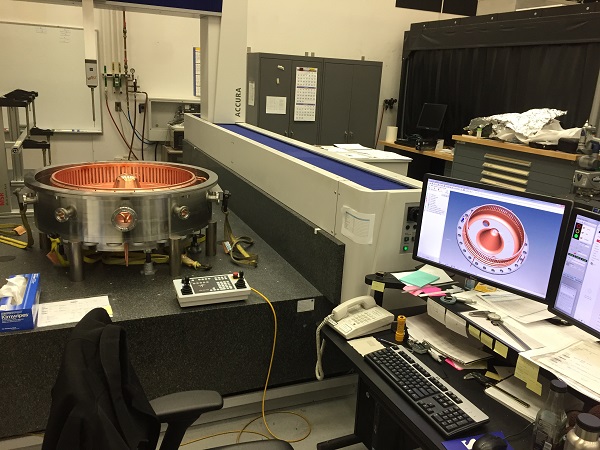

Precision Measurement Services exists for those customers requiring precision measurement, inspection and alignment of large and small parts. We can work from electronic CAD models in a variety of formats, the actual parts, drawings, sketches and verbal instructions.

Some of our current equipment includes:

- Zeiss Accura Coordinate Measuring Machine with a 1600 x 3000 x 1400 mm measuring envelope. It runs Zeiss Calypso software. It has active and passive scanning using Vast Gold and XXT probe heads. In addition we have the ViSCAN video system so that we can combine touch probe scanning and video together in the same measurement plan. The machines stated accuracy is MPE = 3.5 + L/250 or about +/- 7.5 microns per meter. At the last calibration it was accurate to about 3 micrometers per meter.

- Faro Edge with a 3.7m measuring diameter and a max volumetric deviation of ±0.091mm. This is a portable CMM that can be used in our shop or easily transported to your site and set up requiring only a 110v power. We’ve used this for beam line alignment, part fiducializations and inspection and alignment of parts at remote sites such as Lawrence Livermore Lab and JPL in Pasadena. The FARO Edge also has a laser line attachment for 3D scanning of parts.

- Faro Gage Plus with a 1250mm measuring diameter is similar to the larger Faro Edge arm but can fit in much smaller spaces where the larger arm can’t reach.

- OGP vision machine is a large 750mm x 750mm x 300mm programmable video microscope. It has through the lens coaxial lighting, ring lighting and back lighting. It has exceptional Z focus capabilities and can focus on mirror like or clear surfaces like glass or water. With a laser attachment it can do simple line scans. A feather-touch probe is also installed which provides low contact force (less than 10 µN) measurement capability.

- Standard inspection equipment includes electronic height gages, calibrated gage blocks, ultrasonic micrometer, and all of the standard manual inspection equipment.

NIST traceable Certifications are conducted on a regular basis for a certain sub-set of machines, gages and standards managed by Metrology